In the ever-evolving landscape of medical device innovation, the bridge between concept and reality is often built through meticulous prototyping. For medical device startup professionals, navigating the intricacies of prototyping techniques is akin to sculpting a masterpiece – each stroke and curve holds the promise of transforming ideas into tangible solutions. This journey, however, demands a structured approach and an arsenal of prototyping techniques tailored to the unique challenges of the medical field. In this exploration, we will dive into medical device prototyping, unveiling techniques that can shape the future of healthcare.

Before Prototyping: Laying the Foundation

Before delving into the world of prototypes, clarity is key. Define your problem statement with surgical precision, outlining the precise challenges your device intends to solve. Establish your goals and parameters – the guiding lights that will navigate your prototyping process. With a handful of ideas in your arsenal, refine them to their essence. This distilled creativity forms the bedrock upon which your prototypes will be built. Plan meticulously, for a well-structured blueprint is the scaffolding upon which innovation stands tall.

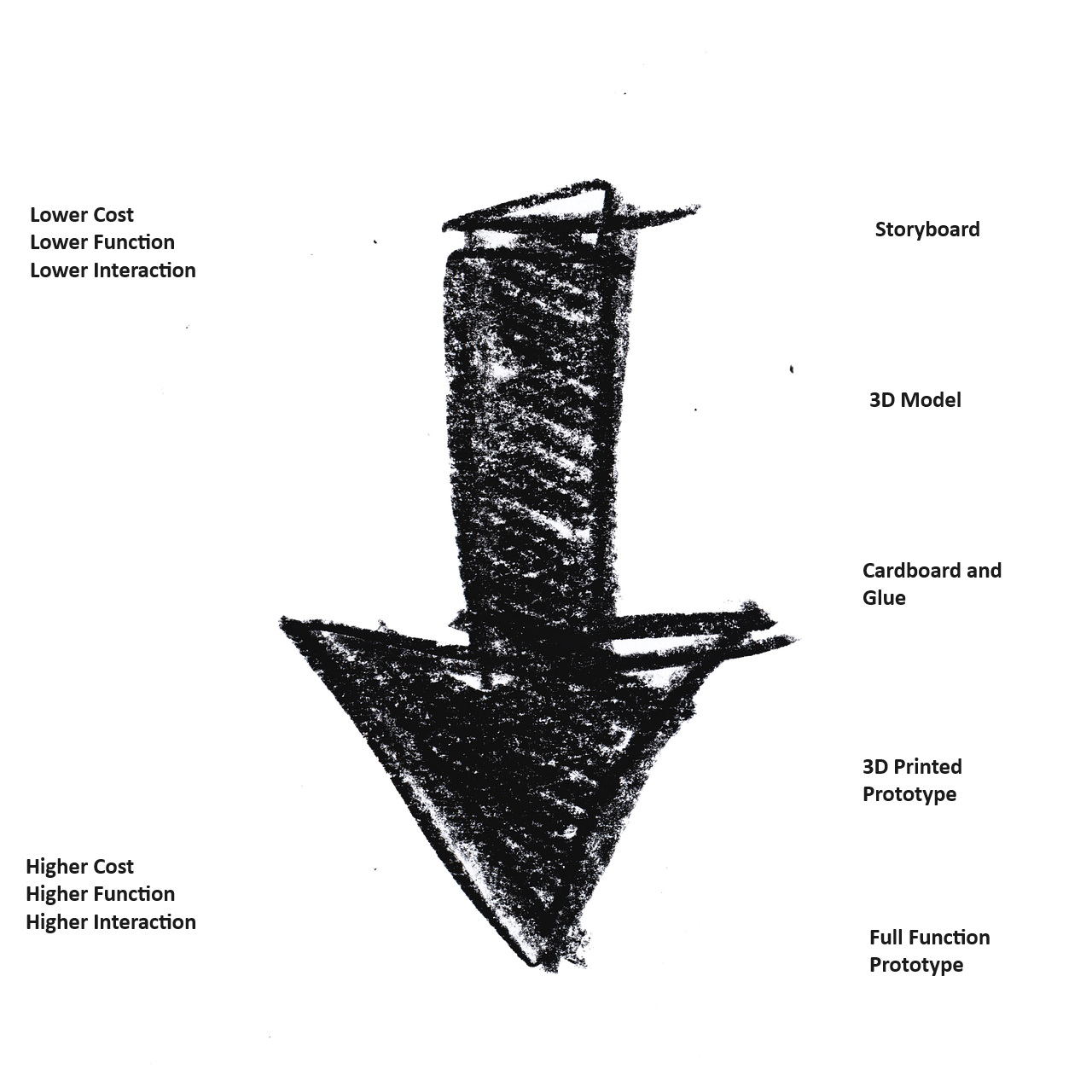

Conceptual vs Full Functioning: Choosing the Right Path

Prototyping, like the medical field itself, comes in varying degrees of complexity. Conceptual prototypes, akin to the sketching phase of an artist, offer a foundational understanding. They are less expensive, providing the ideal canvas for initial ideation and experimentation. In contrast, full-functioning prototypes, the magnum opus of the prototyping world, mirror the final product in functionality. While costlier, they provide a holistic insight into the device’s behavior and serve as the ultimate litmus test before venturing into full-scale production.

Prototyping Techniques: Crafting the Future

Storyboards: Imagine the user experience unfolding like a carefully crafted tale. Storyboards map out this journey, allowing you to walk in the user’s shoes, and understand their interaction with the product.

3D Modeling: With the aid of advanced software, your concepts come to life in a digital realm. Though low in fidelity, 3D models provide a visual representation, aiding in refining the product’s design and structure.

Cardboard and Glue: Here, innovation meets simplicity. Using everyday materials, create low-cost prototypes that can be touched and felt, providing a tangible connection with your concept.

3D Printing: A technological marvel that elevates the tactile experience. 3D printing allows for a more in-depth interaction, enabling you to identify nuanced improvements while maintaining a relatively low prototype cost.

Full Build Prototypes: The crescendo of the prototyping symphony. Full builds emulate the final product, providing an unparalleled understanding of its functionality. This stage acts as the last canvas before production, where every detail is scrutinized, ensuring the device is primed for real-world application.

Conclusion

In the realm of medical device startups, prototyping is not just a phase; it’s an art, a science, and a testament to relentless innovation. Each technique, from the humble cardboard model to the intricate 3D print, paints a facet of the future of healthcare. As you navigate this path, remember: prototyping is not merely about creating replicas; it’s about crafting possibilities. So, let your ideas take form, let your concepts breathe, and let your prototypes echo the future you envision. In each prototype, lies a step toward revolutionizing healthcare. Embrace the process, for in your hands, you hold the power to transform lives.

Image by Gerd Altmann from Pixabay with modifications (arrow)

Image by RAEng_Publications from Pixabay (Title)

Written with the help of ChatGPT

Leave a comment