In the ever-evolving world of medical device development, adherence to rigorous regulatory standards is paramount. One of the fundamental elements of this compliance is the Design History File (DHF). In this comprehensive guide, tailored to medical device startup professionals, we will delve into the critical aspects of DHF. We’ll explore what it is, its significance in regulatory compliance, its contents, and essential tips for building and maintaining an effective DHF.

What is a Design History File(DHF)?¹

A formal, organized documentation of product design and development processes for medical devices. The DHF is the backbone of the design controls process. It is mandated by the U.S. Food and Drug Administration (FDA) and is similarly required by international standards like ISO 13485. It serves as a meticulously maintained organizational tool, a roadmap that demonstrates proper compliance and documentation throughout the product development journey.

Crucial part of the design control process mandated by the FDA. Regulatory authorities, like the FDA, require medical device manufacturers to implement design controls to ensure the safety and effectiveness of their products. The DHF is the tangible manifestation of these controls, providing an auditable trail of the product’s design and development history.

Preparing for and passing FDA audits. In the heavily regulated landscape of medical devices, FDA audits are commonplace. A well-maintained DHF can make the difference between a smooth audit process and regulatory headaches.

What is a DHF used for?³

Regulatory Compliance

Both the FDA regulations (21 CFR 820.30) and international quality management standards like ISO 13485 (7.3.10) require the establishment and maintenance of DHFs. Compliance with these standards is not optional; it’s a legal requirement.

Traceability

The DHF provides a clear and traceable record of the design and development journey. It should contain information on the device’s design inputs and outputs, verification and validation processes, design reviews, design transfers, and any changes made throughout the development process. This traceability is essential for demonstrating that the final product meets its intended requirements and is safe for its intended use.

Quality Management

The DHF plays a pivotal role in maintaining the quality and consistency of your product. It allows you to track and manage design changes, ensuring that they are properly evaluated and documented, thus reducing the risk of errors and discrepancies.

Audits and Inspections

Regulatory authorities, notified bodies, and other stakeholders may request access to your DHF during audits or inspections. A well-organized and comprehensive DHF can streamline these processes and instill confidence in the auditors that your organization is committed to maintaining the highest quality standards.

What does a DHF include?²

Design and Development

The DHF should encompass all stages of design and development. This includes initial concepts, feasibility studies, risk assessments, design planning, and concept selection. Each step should be meticulously documented, showing how the product evolved from idea to reality.

Design Input and Output

Design inputs define the requirements and expectations for the device, such as user needs, intended use, and regulatory requirements. Design outputs, on the other hand, detail how these requirements are met through design and development.

Design Verification and Validation

The DHF must provide evidence of design verification and validation activities. Verification confirms that the product meets specified requirements, while validation ensures it performs as intended in real-world scenarios.

Design Reviews, Transfers, and Changes

Any design reviews, transfers between teams or facilities, and changes to the product’s design should be thoroughly documented within the DHF. This includes records of discussions, decisions made, and actions taken.

Tips for Building Your DHF⁴

Give yourself enough time

Developing a robust DHF takes time. It’s not something you can rush through at the end of the project. Plan for its creation from the project’s inception and allocate resources accordingly.

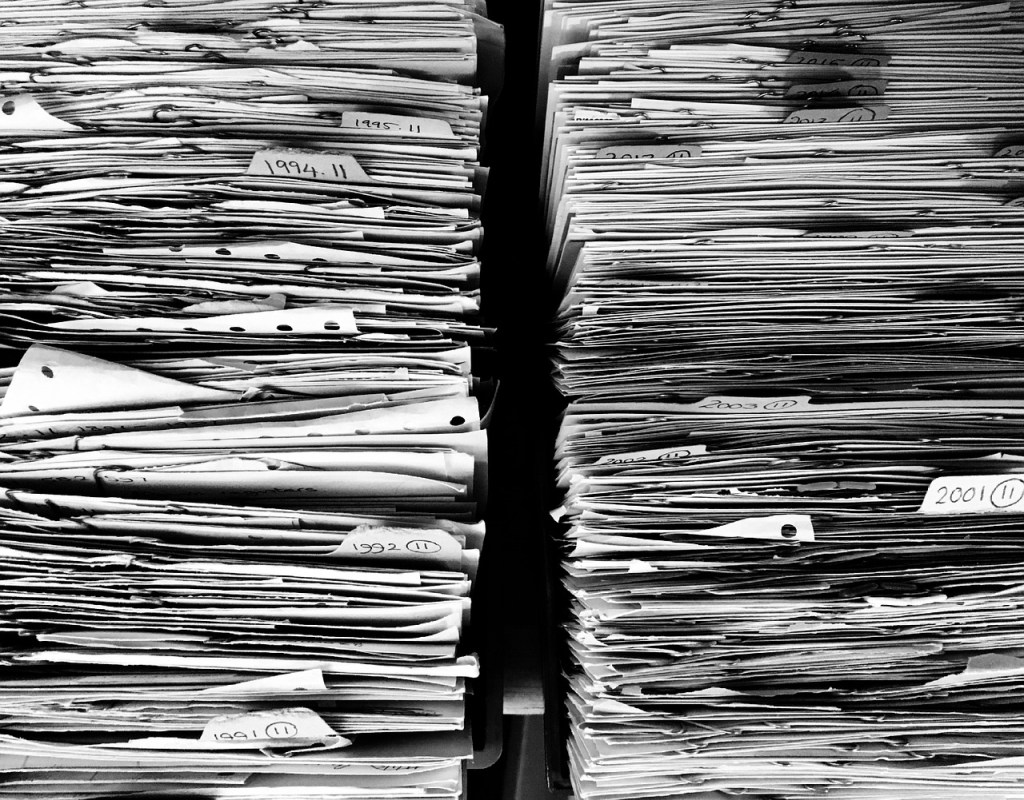

Keep it well-organized

Ensure your DHF is well-structured and organized. Use clear naming conventions, logical folder structures, and an indexing system to make information easy to find.

Keep the DHF separate

Your DHF should have its own dedicated space, separate from other project files and documents. This separation ensures that the DHF remains focused and uncluttered.

Provide traceability

Establish traceability between elements within the DHF. For instance, show how design inputs relate to design outputs, and how design verification and validation activities align with specific requirements.

Conclusion

In the world of medical device development, meticulous attention to detail and compliance with regulatory standards are non-negotiable. The Design History File (DHF) is your key to navigating this complex landscape. It is not just a box to tick; it’s a comprehensive record of your product’s journey from concept to reality, a testament to your commitment to quality and safety.

As a medical device startup professional, understanding the significance of the DHF and following best practices for its creation and maintenance is essential for success. Embrace it as a tool for not only achieving regulatory compliance but also for ensuring the highest standards of quality, safety, and traceability in your product development process. In the end, a well-maintained DHF can be the cornerstone of your success in the highly regulated world of medical devices.

Sources

- https://www.greenlight.guru/glossary/design-history-file

- https://sterlingmedicaldevices.com/thought-leadership/design-history-files-everything-you-should-know/

- https://rookqs.com/solutions/dhf-tf-creation/

- https://13485store.com/iso-13485-requirements/section-7-product-realization/design-and-development/iso-13485-medical-device-design-records/

Written with the help of ChatGPT

Leave a comment